Multifunctional Tunnel Boring Machine for Loess Tunnel

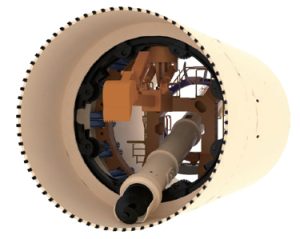

The Loess multi-functional TBM integrates excavation, support and slag discharge. It is suitable for loess tunnel construction. It has the functions of advanced support, fitting special-shaped section and bad geological treatment.

The construction methods can be flexibly matched according to the geological conditions of the tunnel. According to different construction methods, the main machine length and equipment length of the Loess multi-functional TBM can be flexibly designed to ensure the safety of tunnel construction.

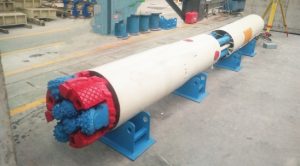

Micro TBM

The Micro TBM of a project mainly crosses granite, and the maximum uniaxial compressive strength is 220MPa. ZTT550 micro TBM, with excavation diameter of 550mm, adopts vacuum slag removal system to realize excavation and rapid slag removal in ultra-small space.

| Item | Parameter | |

| Equipment type | ZTT550 | ZTT550 |

| Overall length / total installed power | 30m/ 335kW | About 30m / about 335kw |

| Excavation diameter / main drive power | 0.55m/132kW | 0.55m/132kW |

Rapid Laying and Jacking Machine

The rapid laying and jacking machine uses the tunnel boring machine for tunnel excavation, and the tail of the tunnel boring machine is welded with the pipeline. With the continuous forward excavation of the tunnel, the pipeline is continuously pushed into the stratum by the rear pipe pusher. When the tunnel excavation is completed, the pipeline installation is completed at the same time.

It is widely used in pipeline laying projects such as oil, natural gas, water conservancy and hydropower.

1. It is not necessary to install pipe joints or assemble segments during jacking;

2. Simple launching and receiving wells can be made to save construction cost;

3. Compared with the traditional shield method and pipe jacking method, it has higher construction efficiency and no auxiliary process. It can realize 24-hour continuous jacking operation with a daily excavation distance of 100 meters.

| Item | parameters | |

| Equipment type | ZTP1300 | ZTP1505 |

| Host length | about 14m | about 14m |

| Machine weight | about 200t | about 270t |

| Maximum thrust of pipe pusher | 5000kN | 8000kN |

| Maximum construction speed of pipe

pusher |

5m/min | 5m/min |

| Construction angle | -15° ~15° | -15° ~15° |

| Installed power | about 770kW | about 820kW |

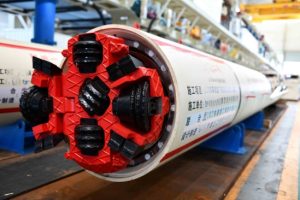

Tube Curtain Machine

The pipe curtain machine adopts steel pipe for jacking to form a “pipe curtain” as advance support, which is mainly suitable for the construction of large section and shallow buried engineering, with the characteristics of small ground settlement and high safety.

1. The pipe curtain machine is suitable for soft soil, hard rock and other strata, and the designed maximum daily excavation

distance can reach 20m;

2. It is applicable to pipe curtain construction without receiving well;

3. The foldable cutter head can realize the overall retreat of the pipe curtain machine, and has the ability to send it into the tunnel again for re excavation;

4. The pipe curtain machine has deviation correction function and can carry out curve construction.

| Item | parameter |

| Equipment type | ZTP720 retractable pipe curtain machine |

| Excavation diameter | 0.74m |

| Overall length | 12m |

| Weight | 63t |

| Installed power | 93kW |

Pipe Roofing Machine

The pipe jacking machine has the same safety and efficiency as the shield machine, and can cross roads, railways, rivers, aboveground structures and tunnels Various underground pipelines have high economic benefits and are one of the main equipment for urban pipe gallery construction.

1. The cutterhead design has strong adaptability to different formation geology;

2. The hinged shield design is conducive to the adjustment of the host attitude during tunneling;

3. The main bearing, main drive seal and main drive reducer with reliable quality are adopted, with large driving torque, long

service life and high safety factor;

4. Reliable and efficient PLC control system, real-time online monitoring and data acquisition;

5. The guidance system has high precision to ensure the smooth progress of tunnel construction.

| Item | parameter |

| Equipment type | ZTP2670 pipe jacking machine |

| Overall length / weight | About 20m / about 117t |

| Cutter head | Composite cutter head, excavation diameter 2.73M |

| Main drive | Hydraulic motor drive, rated torque 768knm |

| Articulation form / minimum turning radius | Active articulation / 150m |

| Number of host nodes | Section 3 |

| Installed power | About 800KW |

Reviews

There are no reviews yet.