Salt Waste Management

99.9% Burning Rate Salt Waste Management Combustion Technologies

Highlight:

salt waste management combustion, combustion salt lake waste management, single screw salt waste management

| Automation: | Automatic | Screw: | Single-Screw |

| Treatment: | Burning | Fuel: | Diesel Oil, Natural Gas, Lps |

| Service Life: | 10-15 Years | Factory Establishment: | 2013 |

| Voltage: | 380V/220V | Blackness Of Exhaustion: | Ringelman <1 |

| Type Of Waste: | Solid Waste | Feeding Type: | Hydraulic |

| Burning Rate: | 99.9% | Emission Standard: | European Standard |

| Transport Package: | Container, Bulk Cargo | Specification: | Customized |

| Trademark: | SINOASIA | Origin: | China |

| HS Code: | 8417809090 | Supply Ability: | 100sets/Year |

| Customization: | Available | After-sales Service: | Installation Guide |

| Warranty: | 1 Year |

99.9% Burning Rate Salt Waste Management Combustion Technologies Automation Included Single Screw

Leading Burning Rate Waste Salt Combustion Technologies Automation Included

Production Description:

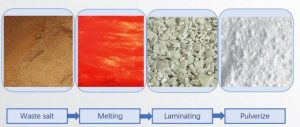

The technology can obtain pure industrial salt through high temperature melting and refining disposal, and the product has been up to standard and stable after long-term engineering practice.

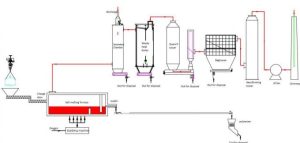

Process Diagram:

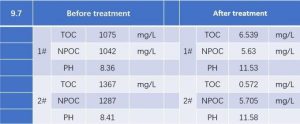

Testing data :

Production Features:

• Total oxygen and low nitrogen combustion

Using pure oxygen to supplement oxygen to achieve true low-nitrogen combustion, the flue gas through the secondary combustion chamber 1100 ºC treatment into the exhaust gas purification system, exhaust gas treatment thoroughly. In the process of incineration and melting, the amount of smoke is small and the amount of auxiliary fuel is small, which meets energy saving and emission reduction requirements.

•Efficient and energy saving melt incineration process

High efficiency and energy saving melting incination process adiabatic furnace high temperature radiation melting, the bottom of the melting pool using kiln cutting isolation technology, the melting pool is isolated into a melting pool and a clarifying pool, the larger proportion of impurities are isolated at the bottom of the melting pool, improve the purity of the molten salt solution, to achieve the most efficient energy saving and environmental protection.

•Oxygen bubble system design, combustion more thorough

The bottom of the molten pool is equipped with a full oxygen bubble system, which speeds up the convection of molten liquid, makes the organic matter in the waste salt burn more thoroughly, improves the purity of salt and shortens the melting time.

• A variety of equipment models to meet the needs of all scales

All non-standard custom design, to meet all kinds of small, medium and large waste salt, salt slag treatment projects, a single processing line processing scale of 5 ~200T/D.

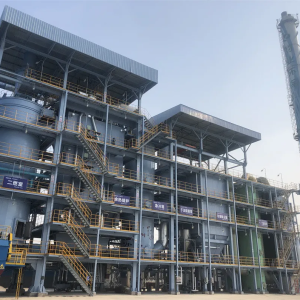

Product Show In production :

Reviews

There are no reviews yet.